There are different ways to detect leaks with a leak detector: with tracer gas or using air.

With tracer gas as a means of detection, there are three options. The spray test is suitable for components under vacuum, and sniffing leak detection is used for components under pressure. An integral leak test is a variant for components that can be put inside a vacuum chamber.

The test methods are easy to perform and deliver accurate results, making a leak detector from Pfeiffer the perfect addition to your vacuum process.

Tracer gas leak detection

With tracer gas as a means of detection, there are three options. The spray test is suitable for components under vacuum, and sniffing leak detection is used for components under pressure. An integral leak test is a variant for components that can be put inside a vacuum chamber.

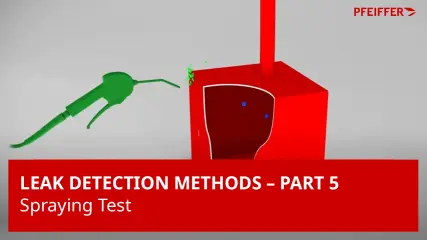

Spray test

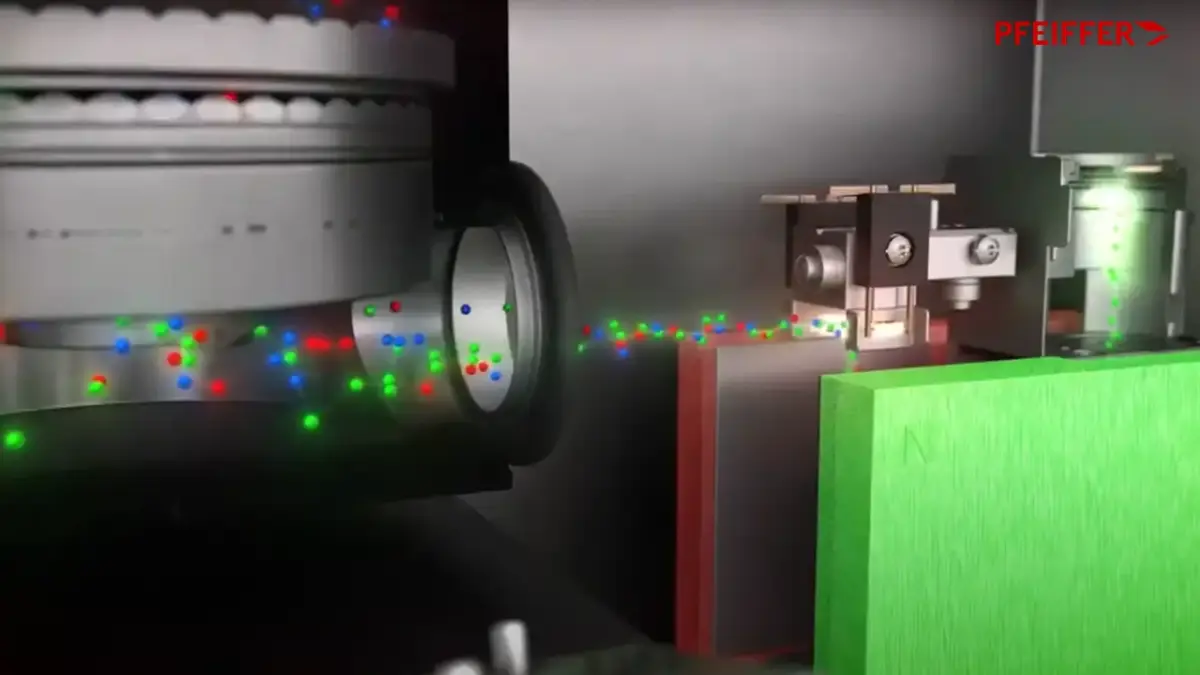

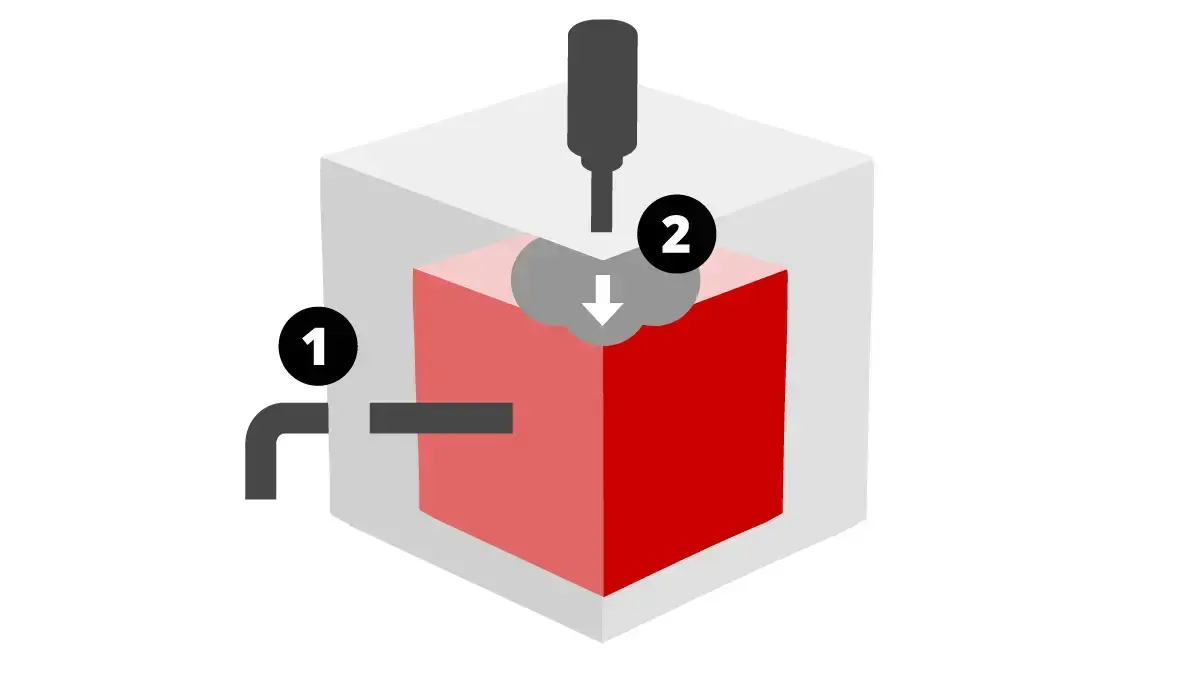

The spray test is the ideal test method for components under vacuum. This measurement principle has the highest sensitivity of all available methods. A vacuum pump removes the air from the test object that is suspected to have a leak, and the leak detector is connected to the test object through a flange. A test object can range from a vacuum furnace to a pipeline, a container, or other pieces of equipment. Helium gas or hydrogen is sprayed onto the outer surface of the test object with a spray gun kit (see figure 1). In the case of a leak, the incoming molecules are drawn in by the leak detector’s integrated turbomolecular vacuum pump and its backing pump. The molecules enter an analyzer cell, which detects the tracer gas.

Sniffing leak detection

Sniffing leak detection is the perfect method for components under pressure. Tracer gas is injected into a test object, such as a piece of equipment, a pipeline, or a container, increasing the internal pressure. A sniffer probe, a tool designed to collect the tracer gas, can be purchased as an accessory and connected to our leak detectors. The operator slowly and systematically guides the sniffer probe over the test object to search for potential leaks (see figure 2). In the event of a leak, escaping tracer gas atoms are detected. This allows the leak points to be localized precisely.

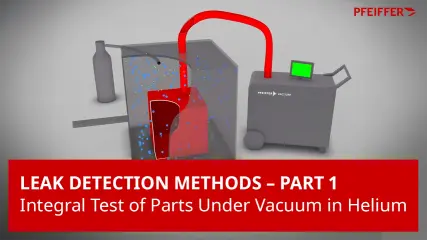

Integral leak detection

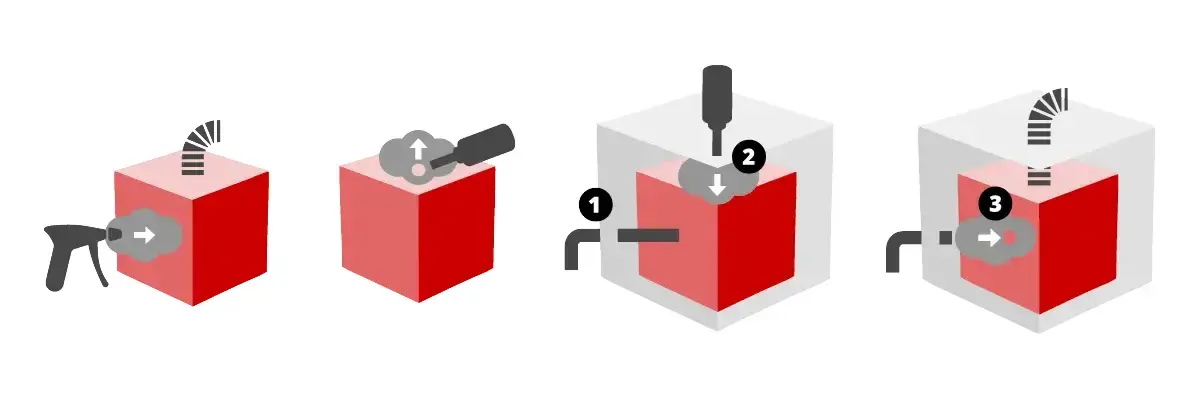

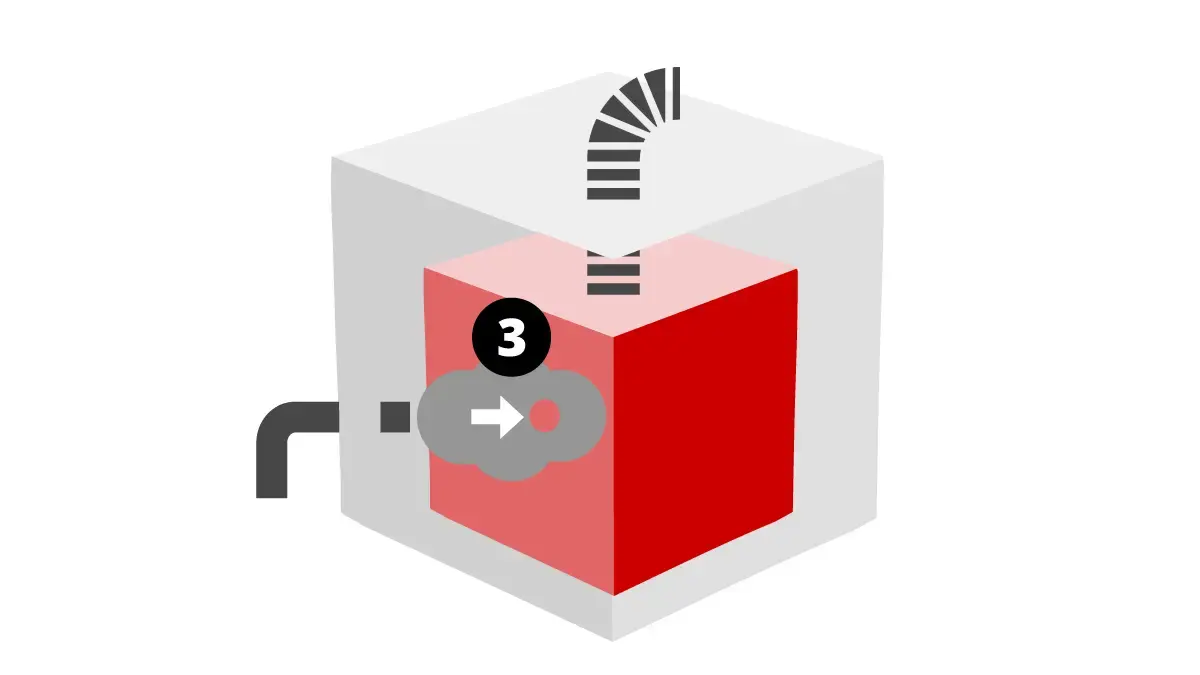

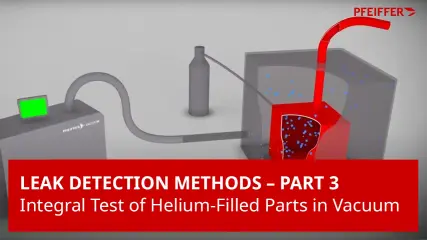

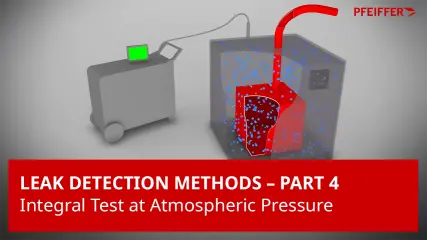

The spray test and sniffing leak detection can both be used for an integral leak detection test. Here, the test object is put inside a vessel, such as a plastic film or a rigid container (illustrated in blue in figures 3 and 4).

Integral sniffing leak detection is carried out at atmospheric pressure. The test object is filled with helium or hydrogen forming gas (1). If there is a leak and the tracer gas starts to escape, it is captured in the vessel. The sniffing probe determines the increase in its concentration over time and measures the leakage rate (2).

For an integral spray test, the test object is connected to the leak detector and placed inside a vessel (3). Just like a conventional spray test, integral spray tests are performed under vacuum. However, while a conventional spray test evacuates the test object itself, this method evacuates only the surrounding container. The vessel is then filled with a defined quantity of helium. This ensures precise test conditions and accurate results. If there is a leak, then helium will penetrate the test object due to the pressure differential. The leak detector measures the amount of helium inside the test object and determines the leakage rate. Integral leak testing methods, however, cannot localize the leak.

Air leak detection

Another method is using an air leak detector. These use our patented Micro-Flow sensor to measure how much air flows from a reservoir to make up for the air lost due to a leak. The Micro-Flow sensor can be used to detect leaks in objects under pressure or in objects under vacuum by using Mass Extraction, a special method using the Micro-Flow sensor.

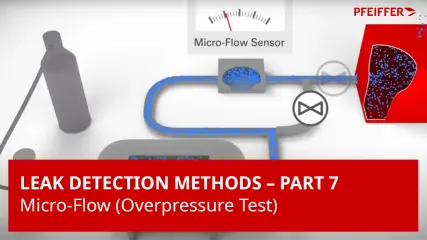

Micro-Flow

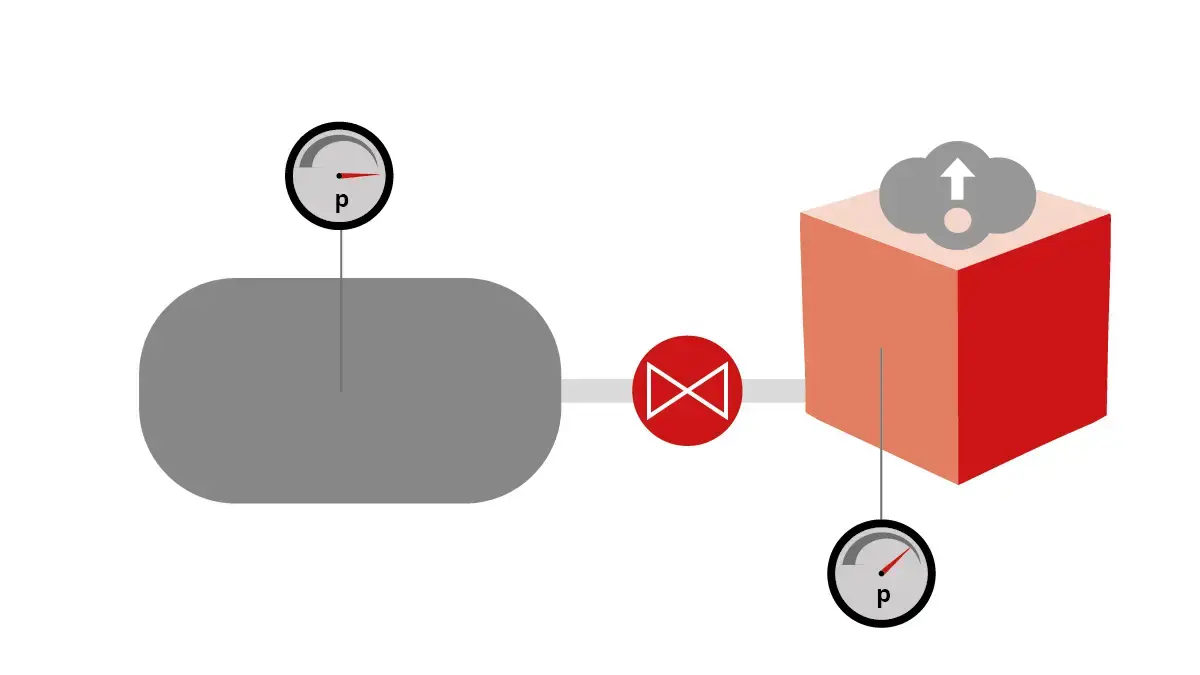

First, the test object is connected to the test set-up. This comprises the leak detector and an air reservoir. The test object is then pressurized with air from the reservoir to a predefined pressure level. If there is a leak, the air will leak out of the test object.

This set-up continuously replenishes the gas flow to compensate for the lost air, thus maintaining the pressure. The replenished gas flow passes from the reservoir through a specially designed sensor, the Micro-Flow sensor. This sensor is equipped with patented technology that amplifies the signal, making it possible to measure even very low leakage rates down to 5 · 10-4 mbar · l/s.

This technology is non-destructive, leaving the test object intact. It provides quantitative results without the need for daily calibration, making it highly reliable and efficient for various industrial applications.

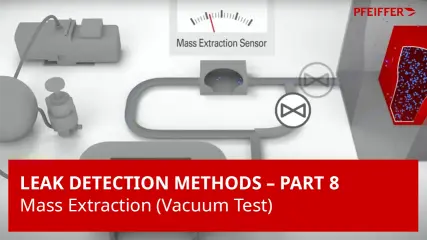

Mass Extraction

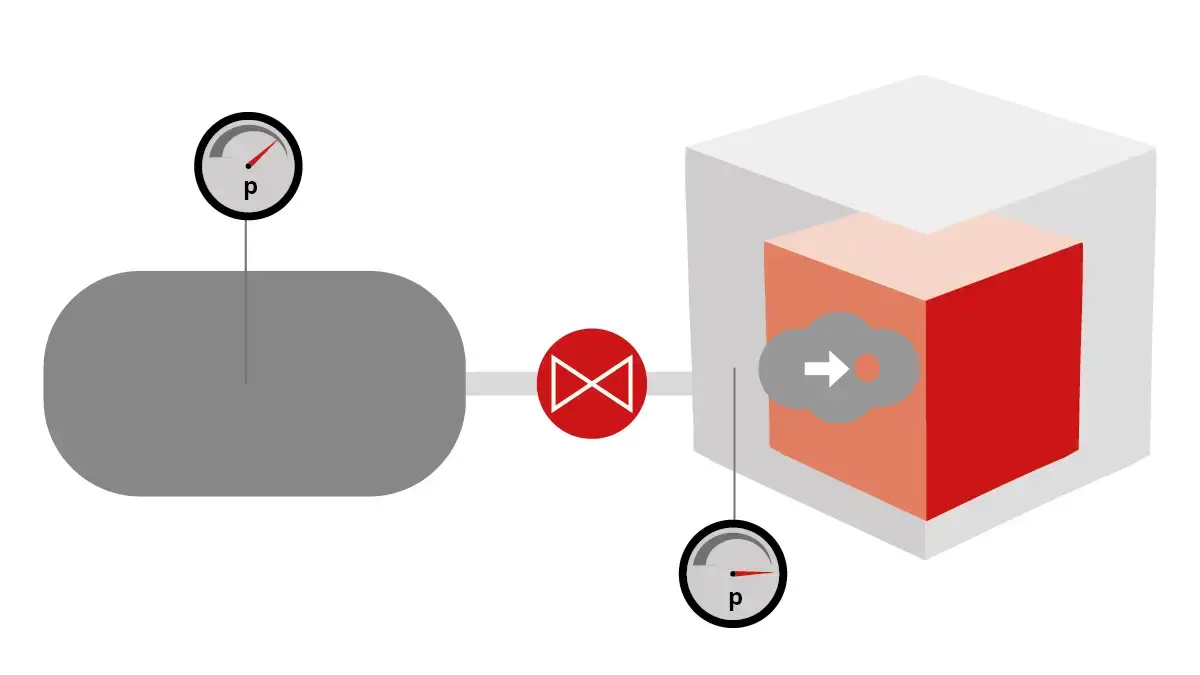

The Mass Extraction method also uses the Micro-Flow sensor, but is carried out under vacuum. This results in an improved detection limit and ensures that there is no heat transfer due to the insulating effect of vacuum.

In the first step of Mass Extraction, the test unit is placed in a vacuum chamber. This chamber is connected to the leak detector, containing the Micro-Flow sensor, and an air reservoir. The chamber is then evacuated. The leakage rate of the test unit is determined by the flow from the reservoir to the test unit. With this method, a detection limit of down to 7 · 10-7 mbar · l/s can be achieved and defects as small as 1 μm can be detected.