Advanced vacuum technology for the semiconductor industry

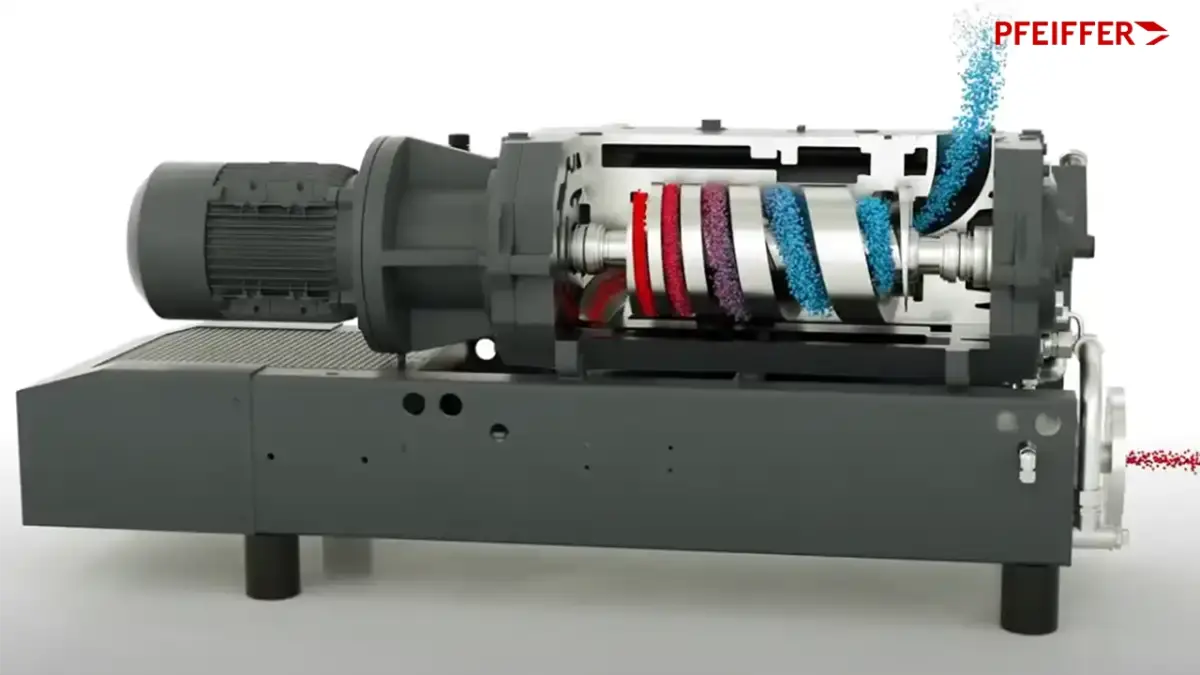

Dry screw vacuum pumps provide high pumping speeds and clean vacuum environments thanks to their innovative operating principle. Inside the vacuum pump, two screw rotors rotate in opposite directions. Vacuum is generated by trapping and transporting the pumped medium in the spaces between the screw rotors and cylinder. The size of these chambers decreases continuously, compressing the pumped medium until it is expelled through the outlet.

Screw vacuum pumps operate contact-free and without oil in the compression chamber, ensuring reduced maintenance requirements and low operating costs. These vacuum pumps are engineered for the most demanding processes in semiconductor manufacturing, including microchip production, silicon wafer coating, and etching.